2020-07-24 8164

In March 2020, Sukami super large ceramic plate intelligent press was officially put into operation in Guangdong Zhongyan Enping production base, with the maximum capacity to suppress 1600×3600mm super large size slabs. This move initiated the cooperation between the domestic brand and the technology of Italy's Sacmi, which has been closed to the outside world, and realized the milestone leap of the intelligent production of China's SLATE.

Sacmi continua + new pulse technology focusing on rock plate industry, precise ceramic plate new market demand, 38000 tons of continuous rolling machine big board production line is set by the international press tonnage and product specifications of the records, the rock in the depth cooperation with sacmi, in rock with amazing drive up domestic plate's backbone, play the melody of intelligent rock plate production.

1

The birth of 1600×3600mm super large SLATE has brought a strong visual impact and spiritual shock to xiaobian. Guangdong Zhongyan shows the industry a giant SLATE ship full of intelligent creativity.

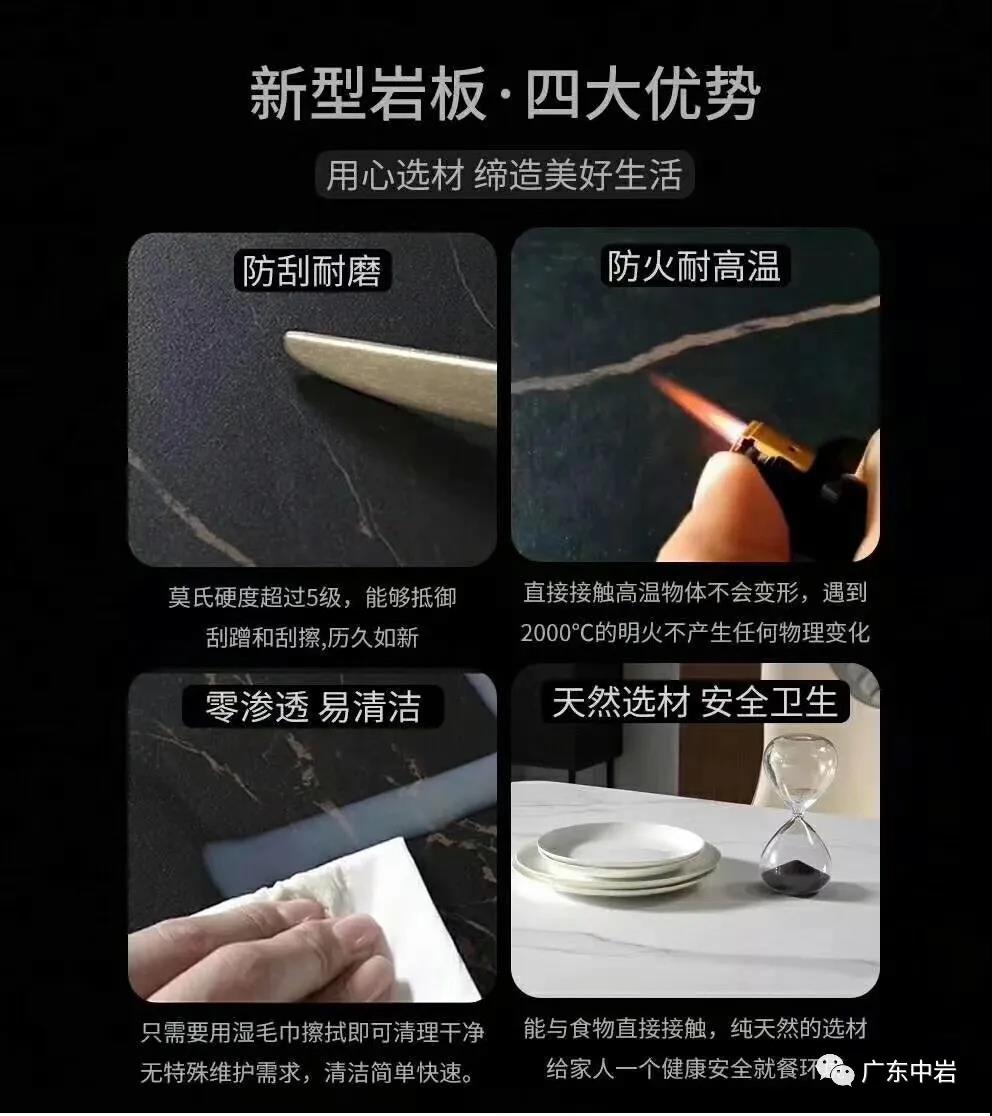

With advantages in strength and toughness, the slabs can be further processed and the traditional ceramic tile sales limitations can be broken to realize the integrated development of cross-boundary resources. The SLATE mainly crosses the boundary the pan-household domain, nibbles the stone, the quartz stone and the wood and so on original market share. Different specifications and thickness of the board have their own different market, such as in the field of table panel, the 15mm thickness of the board operation is more mature; When application waits for cupboard door in ambry, wardrobe, it is the product of thin rock board more.

2

The CONTINUA+ operation is simple and fast, and the upgraded automatic equipment is adopted. If only the width and thickness of the brick are changed and the parameters are entered on the computer, it can be adjusted in 1-2 minutes. If the upper steel belt is replaced, it takes about 20 minutes, even if all relevant equipment changes the size and specification of the brick. The width and final length of the finished product can be selected and fixed, only need to change the blank cutting position of the pressed material, the typical standing values in production are 1200 mm, 2400 mm, 3000 mm, 3200 mm and 3600 mm.

The efficiency, quality and accuracy of the new generation DHD series inkjet printers have been significantly improved.

3